The “Spark Plug” or, simply the “Plug” has been around for a lot longer than you may imagine, in fact from as far back as 1860 when Étienne Lenoir used an electric spark plug in his internal combustion engine.

The “Spark Plug” or, simply the “Plug” has been around for a lot longer than you may imagine, in fact from as far back as 1860 when Étienne Lenoir used an electric spark plug in his internal combustion engine.

Early patents of the spark plug included names that you will be familiar with to this very day. Nikola Tesla of the United States, Frederick Richard Simms and Robert Bosch both of Great Britain all submitted patents in 1898.

Subsequent manufacturing improvements were made by Albert Champion, Lodge Brothers (plugs with distinctive pink ceramic insulators) and by Kenelm Lee Guinness (an Irish born racing driver of the Guinness brewing family mainly associated with Sunbeam Racing Cars in the early 1900’s). Kenelm was also an automotive engineer and thus he developed the brand of spark plugs that sported his initials, that of KLG.

KLG spark plugs (like that of Lodge) were later purchased by Smith Industries until the factory was demolished in 1989. Stocks (although limited) of KLG plugs are still available to this day from specialist Companies, like the Green Spark Plug Company.

Unlike the modern spark plug, earlier spark plugs were made to be dismantled and cleaned, many had a 2BA threaded top electrode, spring clip and/or a knurled nut used to accept an HT cable’s un-insulated cable or lug. Most modern spark plugs now use a 4mm thread with a threaded top (SAE Bullet Terminal), which depending upon the type of HT Plug Cap used may or may not be fitted.

Unlike the modern spark plug, earlier spark plugs were made to be dismantled and cleaned, many had a 2BA threaded top electrode, spring clip and/or a knurled nut used to accept an HT cable’s un-insulated cable or lug. Most modern spark plugs now use a 4mm thread with a threaded top (SAE Bullet Terminal), which depending upon the type of HT Plug Cap used may or may not be fitted.

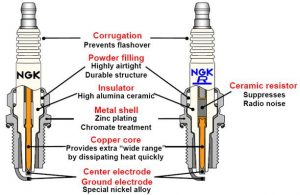

There are a multitude of spark plugs on the market of different manufacturers, types, shapes and sizes, however they all work on the same basic principle and perhaps this will help you understand a little bit more about these invaluable pieces of kit, essential to  the majorities of engines.

the majorities of engines.

They are available in differing make up (resistor, non resistor) thread sizes, depth of thread (long reach short reach etc.), spanner sizes and working temperatures (hot and cold plugs), some of which we hope to explain within.

Spark plugs are designed to have an adjustable spark gap (the space between the centre electrode and the ground electrode), this adjustment is achieved by careful bending the ground electrode very gently. This allows for situations where the same spark plug, which may be specified for several different engines requires a different gap for each.

Generally speaking this gap is around 0.6mm to 1.8mm (0.024” to 0.071”, often expressed by us oldies in “thou’s” or thousandths of an inch).

Measuring this gap is most commonly done using a set of precision Feeler Gauges, slithers of steel and brass with their thicknesses commonly marked off in both Metric and Imperial.

Measuring this gap is most commonly done using a set of precision Feeler Gauges, slithers of steel and brass with their thicknesses commonly marked off in both Metric and Imperial.

Another really handy piece of kit for doing this is a round pocket size “Gap Gauge” which is basically a disc with a sloping lipped edge around its circumference and dimensions inscribed above this edge, 20 thou to 100 thou on the example shown. The edge is thicker as you go anti-clockwise and so it can also be used as a progressive gap widener, it’s a handy little piece of kit to have in your bikes toolbox.

On the subject of the actual specified gap, a narrower gap than recommended may give too small and weak a spark to ignite the mixture properly, a gap too wide may prevent a spark from firing at all (or misfiring at high speeds) and gaps can alter (widen) with usage. A lot of engine problems can be traced to problems with the ignition system and in turn with the spark plugs, for whatever reasons, as they may have developed a fault in service.

Our own number one rule is never economise on spark plugs, always carry spares, they cost very little & its not worth the trouble, if in doubt replace them and do not automatically assume that your new replacement plugs mean that you have to look elsewhere for a problem that persists.

There have been more than one of us caught out on that assumption in the past, thinking that “it can’t be the plugs, I’ve only just replaced them!” and so we have gone on to replace more expensive items (coils etc) all to no avail. To the experienced a faulty batch of plugs is not unknown; likewise, there have also been some counterfeit plugs on the market as well, that have caused some of our colleagues an awful lot of grief, always buy from a reputable source, keep plenty of spares and you won’t go far wrong.

How to understand a Spark Plug from visual inspection

How to understand a Spark Plug from visual inspection

Regular inspection of your spark plugs will provide you with a very good indication of how your engine is running and as such many handbooks provide photos of typical spark plug electrode conditions. Generally speaking when a spark plug is operating at its optimum temperature and the engine is in good condition the electrode will be seen to have a light tan/grey colouring, which will indicate that all is well.

An example of this can be seen in the first photograph.

An example of this can be seen in the first photograph.

A much darker colouring and the presence of heavy black (wet or dry) deposits is usually an indication of an engine running in a far too rich condition. This can also be an indication of an incorrect spark plug being fitted (too cold a heat range of spark plug). It can also be an indication of too large a plug gap, overly retarded ignition timing, a possible vacuum leak or even low compression.

If these deposits are wet, depending upon the make up of the liquid deposit on the spark plug, it may just lead to signs of over rich carburation, or in the case of oily deposits, a possible blown head gasket, oil passing the rings or valve gear, which will obviously require further investigation.

Fouling of either a wet or dry nature will obviously reduce the resistance between the centre electrode and the ground electrode, although we were somewhat surprised to hear from one particular source that an engine might still be able to start normally with such a resistance as low as only 10Ω (10 Ohms).

Fouling of either a wet or dry nature will obviously reduce the resistance between the centre electrode and the ground electrode, although we were somewhat surprised to hear from one particular source that an engine might still be able to start normally with such a resistance as low as only 10Ω (10 Ohms).

In the case of a spark plug/engine overheating the appearance of the electrode area will be much whiter and in the case of overheating often small accumulated deposits on the insulator tip can melt giving the insulator tip a rather glossy and glazed appearance. As with all such abnormal spark plug conditions, immediate attention is recommended to resolve the problems before irreparable damage is caused to the engine.

There are other indications, including obvious mechanical damage, abnormal electrode erosion, melting and oxidisation, but those mentioned above are the more common. There will, of course, be normal high mileage wear and tear which can erode the ground electrode and increase the spark plug gap, reducing its efficiency making it require higher firing voltages, which can put a extra strain on the whole ignition system.

Normal rates of spark plug electrode wear (increasing gap growth) are as follows:-

· Four Stroke Engines: 0.01 to 0.02mm per 1,000km (0.00063” to 0.00126” per 1,000 miles), which is an average gap widening of just under 1 Thou (0.009”) per 10K miles ridden/driven.

· Two Stroke Engines: 0.02 to 0.04mm per 1,000km (0.000126” to 0.00252” per 1,000 miles), which is an average gap widening of about 1.3 Thou (0.0013”) per 10K miles ridden/driven.

Spark Plug Operating Temperatures

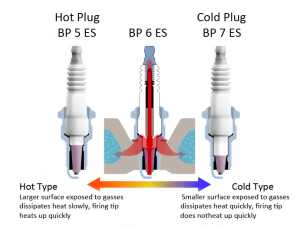

Ever wondered what a person is referring to when they say that a particular spark plug is a “hot” plug or a “cold” plug?

Ever wondered what a person is referring to when they say that a particular spark plug is a “hot” plug or a “cold” plug?

The operating temperature is the actual physical temperature generated at the tip of the plug when it is operating within a running engine, which is normally between 500°C and 800°C (932°F and 1,472°F).

A spark plug is referred to as being “hot” if it is a better heat insulator and it keeps more heat in the tip of the spark plug, whilst a spark plug is referred to as being “cold” if it can conduct more heat out of its plug tip, thus reducing its tip temperature.

This is known as the “heat range” of the plug and it is typically quoted as a number within the  plug type, although some manufacturers use ascending number for hotter plugs, others can do the opposite, so this needs to be checked.

plug type, although some manufacturers use ascending number for hotter plugs, others can do the opposite, so this needs to be checked.

The Heat Range Cross Reference Chart illustrates the difference in various manufacturers use of spark plug numbering for progressively “hot” and “cold” plugs.

A Bosch spark plug with a number 2 is a “cold” plug by comparison a NGK number 2 is far “hotter”.

Spark Plug Identification

Every spark plug is identified by its own unique set of numbers and letters and to many these are a bit of a mystery but they all do have a meaning.

You will find below a small sample of some of the various manufacturers identification charts/numbering systems. So, for example a Bosch spark plug type marked XR5DC would have X (M12 x 1.25 thread, with a 17.5mm hexagon), R (would be fitted with a suppression resistor), 5 (would have a medium to cold Heat Range), D (19mm reach, 17.5mm thread & 3mm tip protrusion), C (copper core & nickel ground electrode).

The following Bosch Type Code chart illustrates the yellow and grey lines from the above chart, which complete the identification to provide details of the centre electrode material and the version.

The following Bosch Type Code chart illustrates the yellow and grey lines from the above chart, which complete the identification to provide details of the centre electrode material and the version.

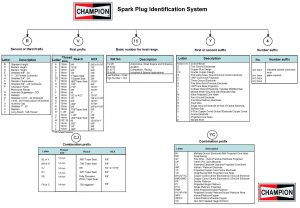

Another famous name is that of Champion Spark Plugs, which is now an integral part of Federal-Mogul Powertrain, who has a UK distribution depot in Bradford (with a very helpful technical section that I have used in the past). They are a global Company, have their World Headquarters in Michigan, USA and a dedicated motorcycle/racing website which can be found at http://championpowersports.eu .

Champion’s Mondovia-Italy team is responsible for the motorcycle side of the business and their main UK distributors are Bickers who can be found at http://bickersplc.com

Champion did produce several spark plugs available with two different sizes of hexagons, as can be seen from the older Identification Chart below (with Imperial dimensions), which we have left within for it’s historic interest.

An up to date version of a Champion (Federal-Mogul Powertrain) identification chart does follow this one.

The recommend Champion spark plug for my early Hinckley Bonneville, is an RA6HC which can be identified from the above chart as R (built in Resistor), A (M12 x 1.25 thread, 19mm reach with a 16mm hexagon), 6 (of medium to cold heat range), HC (Copper core with Nickel ground electrode and 0.8mm spark gap)

The recommend Champion spark plug for my early Hinckley Bonneville, is an RA6HC which can be identified from the above chart as R (built in Resistor), A (M12 x 1.25 thread, 19mm reach with a 16mm hexagon), 6 (of medium to cold heat range), HC (Copper core with Nickel ground electrode and 0.8mm spark gap)

DENSO is a Japanese manufacturer of spark plugs; the name was derived from two words Den-Ki (meaning Electric) and So-Chi, (meaning equipment).

DENSO is a Japanese manufacturer of spark plugs; the name was derived from two words Den-Ki (meaning Electric) and So-Chi, (meaning equipment).

The charts below should assist in identifying Denso spark plugs.

A Denso X27EPR-U9 can thus be identified as X (12mm thread, 18mm hexagon), 27 (mid heat range), E (with gasket a 19mm reach), P (1.5mm tip projection), R (built in resistor), -U (u-groove in ground electrode), 9 (0.9mm, 0.035″, 35 Thou gap)

The Heat Range Chart (as per the one earlier on in this article) illustrates the fact that Denso and NGK use lower numbers for hotter plugs and higher numbers for colder plugs, whereas Bosch use quite the reverse, they utilise higher numbers for hotter plugs and lower numbers for colder ones.

Champion numbers are a little more confusing as the numbering varies according to the applications. The older chart showing numbers 1 to 25 covering Automotive and small engine applications, 26 to 50 for Aviation, 51 to 75 for Hi-Performance and 75 to 99 for Industrial and Special applications. Differing number ranges are also evident within the Champion/Federal-Mogul Identification Chart, although within the designated ranges, the higher the number the hotter the spark plug.

Regarding Heat Range

For normal use, the selection of a spark plug heat range is a balance between keeping the tip hot enough at idle to prevent fouling and cold enough at maximal power to prevent pre-ignition or engine knocking.

Heat from the combustion chamber escapes through the exhaust gases, the sidewalls of the cylinder and the spark plug itself. The heat range of a spark plug has only a minute effect on combustion chamber and overall engine temperature. A cold plug will not materially cool down an engine’s running temperature. (A too hot plug may, however, indirectly lead to a runaway pre-ignition condition that can increase engine temperature.)

The main effect of a “hot” or “cold” plug is to affect the temperature of the tip of the spark plug and not the working temperature of the actual engine.

NGK are another well-known Japanese manufacturer, their initials being derived from Nippon (Japan), Gaisha (Insulator) & Kaisha (Company).

NGK are another well-known Japanese manufacturer, their initials being derived from Nippon (Japan), Gaisha (Insulator) & Kaisha (Company).

Below you will find the design symbols used to identify NGK spark plugs.

So a DPR8EA-9 NGK spark plug would be identified as D (12mm thread, 18mm hexagon), P (projected insulator type), R (built in resistor), 8 (medium heat plug), E (19mm thread reach), A (firing end special design), -9 (with a 0.9mm spark gap).

Handy Tips

If/when replacing spark plugs always compare the thread lengths and never, ever, inadvertently use a “long reach” plug to replace a “short reach” one, as it will inevitably end up interfering with the piston stroke and/or valves which will cause irreparable damage to the engine on the very first rotation. It is also worth noting that on recommended equivalents different manufacturers may use a different hexagon sizes, requiring different size plug spanners!

For example the spark plugs recommended for my early Triumph Hinckley Bonneville are a NGK DPR8EA-9 (18mm hexagon), equivalent to a Bosch XR5DC (17.5mm hex) and a Denso X27EPR-U9 (18mm hexagon) all of which require a 18mm plug spanner. The Iridium plug recommended for the same bike is a NGK DPR8EIX-9, which again uses a 18mm plug spanner.

HOWEVER when choosing a Champion spark plug, the equivalent is an RA6HC which I found had a 16mm hexagon, requiring a smaller 16mm plug spanner (so I now carry both sizes of plug spanner)!

In the case of the Bonneville (probably other bikes as well) plug spanner cylinder head space can be limited and in actual fact the Champion spark plug, with its smaller hexagon and plug spanner can have a distinct advantage.

In the case of the Bonneville (probably other bikes as well) plug spanner cylinder head space can be limited and in actual fact the Champion spark plug, with its smaller hexagon and plug spanner can have a distinct advantage.

This article should provide you with a better understanding of spark plug identification, the differing types and the code types used. The code on the actual plug won’t necessarily tell you the thread, spanner size or plug reach, but often these are visually quite apparent.

Hopefully, now, you will no longer be confused about heat ratings (and the different scales used by different manufacturers), however visually comparing plugs of the same manufacturer you will see that “Cooler” plugs have more ceramic insulator filling the gap between the centre electrode and the body, effectively allowing more heat to be carried off. “Hotter” plugs have far less ceramic material so that the tip retains more heat.

One of the simple things that has stuck out in my mind and might help you (when you can’t remember the spark gap) is the number at the end of most plugs! This virtually confirms the spark plug gap required, for example 9 being 0.9mm (35 thou), 11 being 1.1mm (44 thou), 13 being 1.3mm (50 thou) and so on.

Most spark plugs are relatively cheap, by comparison to other parts, so our best advice is don’t bother cleaning and fitting old plugs (indeed sometimes this can damage a modern plug). Always carry spares, they cost very little & its not worth the trouble, if ever in doubt – just replace them.

Even then, never automatically assume that your new replacement plugs mean that you have to look elsewhere for a problem that persists (experience tells us that new spark plugs bought from, example, an autojumble can sometimes prove faulty) so, ALWAYS buy from a reputable source.

If you need more in depth information with regard to Motorcycle Electric’s, Ignition systems, Spark Plugs, HT leads, Switches, Dynamo’s. Regulators, Starters and Alternators, why not visit our friends Tim and Tom at the Green Spark Plug Company Ltd, at www.gsparkplug.com

Disclaimer

As with all of our articles we strive to provide a better understanding of the items in question and thus create the articles to the best of our ability with the information that is readily available to us at the time. We can accept no responsibility for any inaccuracies and suggest that if there is something that you are unsure about that you seek further technical advice from the appropriate source. That said, we hope you enjoy the article and have learned something from it.

Michael W George (& John Abram)

.